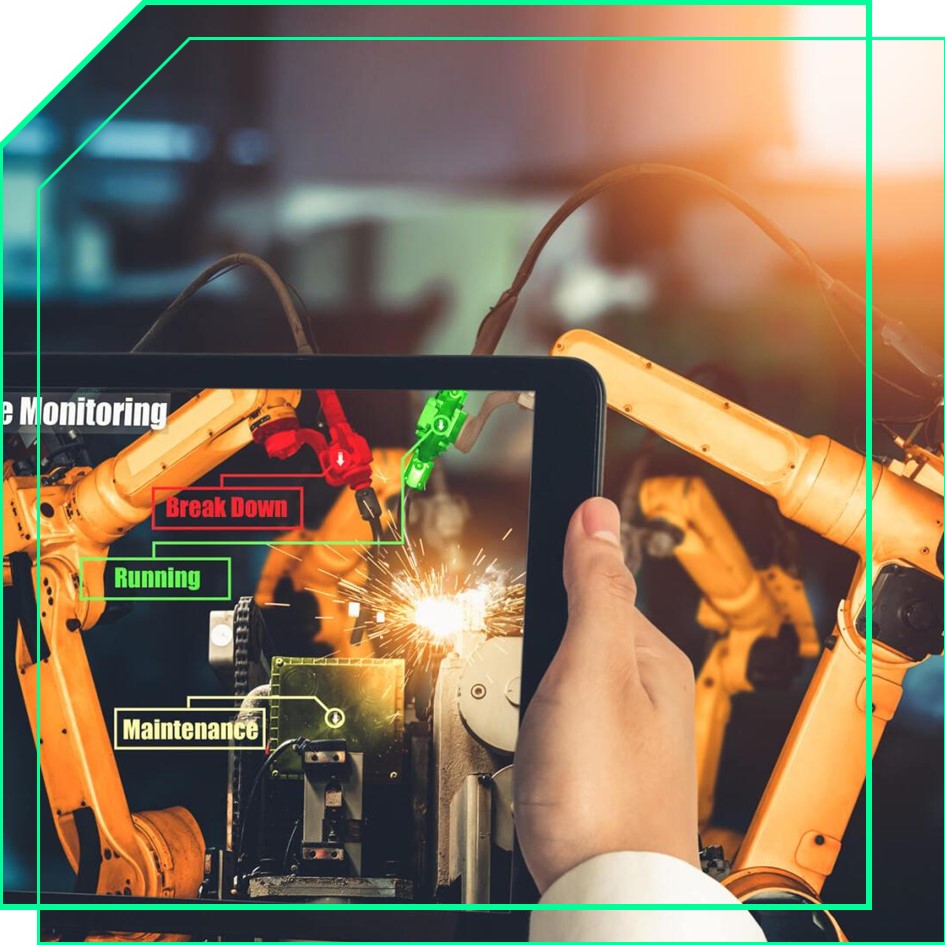

Welcome to the forefront of manufacturing excellence with our Predictive Maintenance solutions, where AI, analytics, Industry 4.0, and IoT automation converge to redefine equipment reliability. As the leading Predictive Maintenance provider in India and worldwide, we pride ourselves on delivering innovative solutions that anticipate and prevent equipment failures. Our state-of-the-art CentralStage platform leverage advanced AI algorithms and real-time analytics, providing businesses with unprecedented insights into the health of their machinery. Seamlessly integrating Industry 4.0 principles and IoT automation, our solutions empower industries to transition from reactive to proactive maintenance strategies. With a global footprint, we offer businesses the tools they need to optimize operational performance, reduce downtime, and stay ahead in the competitive manufacturing landscape. Elevate your maintenance practices with our industry-leading Predictive Maintenance services, where precision meets innovation for a resilient and efficient production environment.

Predictive Maintenance is not just a service; it’s a commitment to operational excellence. Our global recognition as a top Predictive Maintenance provider stems from our dedication to helping industries overcome maintenance challenges. We understand the critical importance of scalability, seamless integration, and the ability to predict potential issues before they disrupt operations. Through our solutions, businesses experience the transformative impact of predictive analytics, ensuring that maintenance is no longer a reactive response but a proactive strategy. Join us on the journey to revolutionize your maintenance practices, as we continue to lead the way in predictive maintenance solutions both in India and across the globe. Explore the possibilities of efficiency, reliability, and sustainability with our cutting-edge Predictive Maintenance expertise.

Unplanned Downtime: Clients often struggle with unexpected equipment failures leading to unplanned downtime, disrupting production schedules and impacting overall efficiency.

Reactive Maintenance Costs: The high costs associated with reactive maintenance practices, where repairs are conducted after equipment failure, pose a significant financial burden for many businesses.

Inefficient Maintenance Scheduling: Traditional maintenance schedules may not align with actual equipment health, leading to either unnecessary maintenance expenses or increased risk of breakdowns.

Limited Asset Visibility: Clients face challenges in obtaining real-time visibility into the health and performance of their assets, making it difficult to proactively address potential issues before they escalate.

Scalability Concerns: As businesses grow, the scalability of maintenance practices becomes a concern, with clients struggling to adapt their strategies to accommodate a larger and more complex equipment portfolio.

Unplanned Downtime: Clients often struggle with unexpected equipment failures leading to unplanned downtime, disrupting production schedules and impacting overall efficiency.

Reactive Maintenance Costs: The high costs associated with reactive maintenance practices, where repairs are conducted after equipment failure, pose a significant financial burden for many businesses.

Inefficient Maintenance Scheduling: Traditional maintenance schedules may not align with actual equipment health, leading to either unnecessary maintenance expenses or increased risk of breakdowns.

Limited Asset Visibility: Clients face challenges in obtaining real-time visibility into the health and performance of their assets, making it difficult to proactively address potential issues before they escalate.

Scalability Concerns: As businesses grow, the scalability of maintenance practices becomes a concern, with clients struggling to adapt their strategies to accommodate a larger and more complex equipment portfolio.

© 2023 CentralStage. All rights reserved.